Medical Device Assembly

Clean, Precise, Repeatable

Our Medical Assembly Systems manufacture high-quality medical components. Machines are designed and constructed for accuracy and a clean production environment, ensuring completed parts are made precise and hygienic; a necessity in the medical industry.

Start a Project With Us

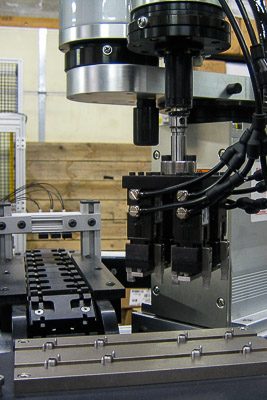

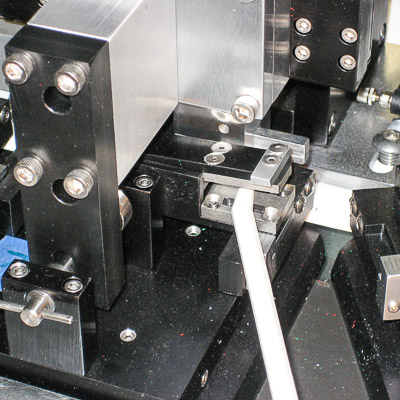

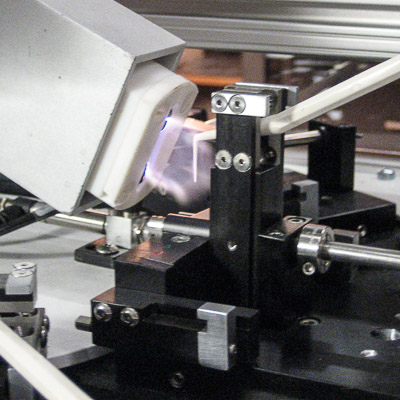

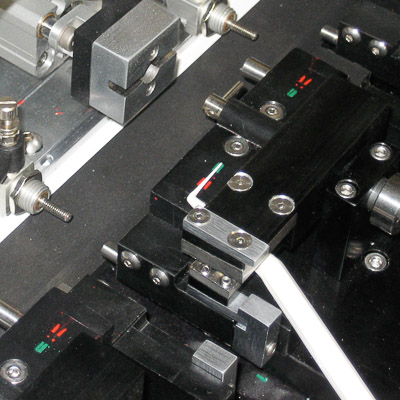

Surgical Device Pin Inserter

Pins are loaded from vibratory feeder bowls down tubes and into an escapement. An operator places the surgical device under the insertion heads. The operator activates the dual-palms. The pins are escaped and pressed into the device.

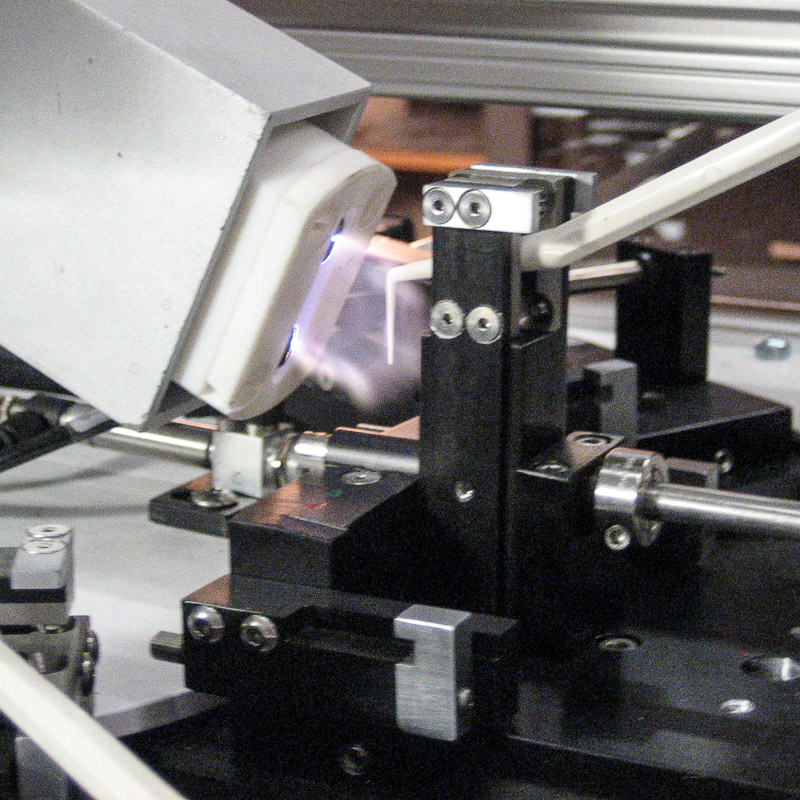

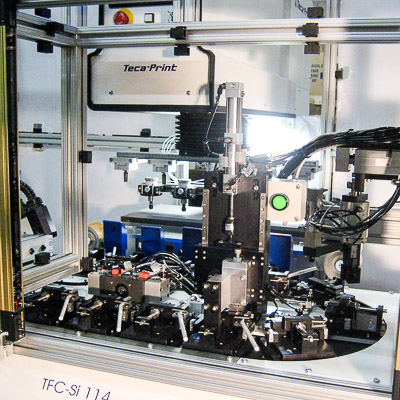

Dental Printing System

Dental tools are loaded by hand onto nests on a carre. The parts index to a corona treatment station where they are raised 90 degrees and hit with corona discharge plasma. The parts cycle to the print stations where they receive two color bands on each side, creating a continuous band in which the two sides cannot be distinguished by eye. The parts are offloaded to a curing oven.

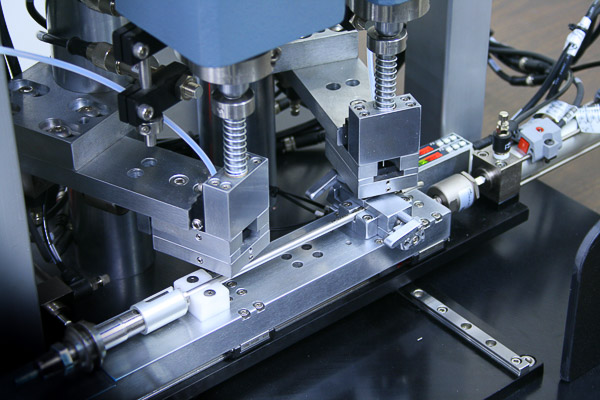

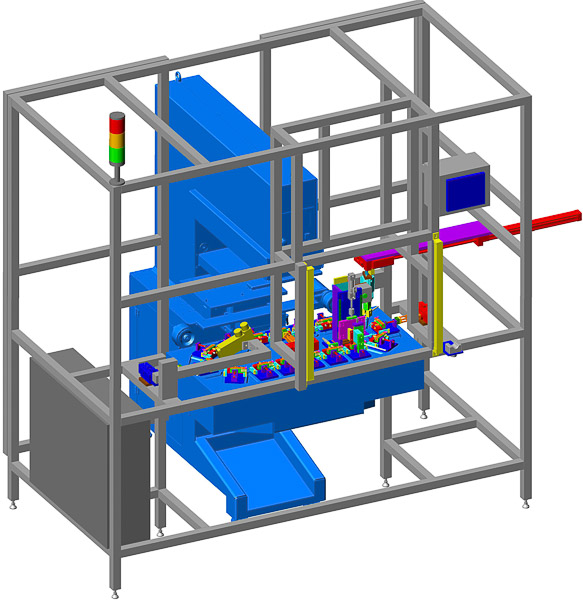

Medical Switch Assembly System

Bottom parts are loaded by vibratory feeder bowl down vibratory tracks and into custom indexing conveyors. Parts are picked up and loaded 8-up onto a rotary dial. Top parts are loaded in a similar manner and assembled onto the bottom parts. The parts are ultrasonically welded and printed with an indicator. A vision inspection system qualifies proper assembly and printed image. Good parts are offloaded to an eject bin and failed parts are offloaded to a reject bin.